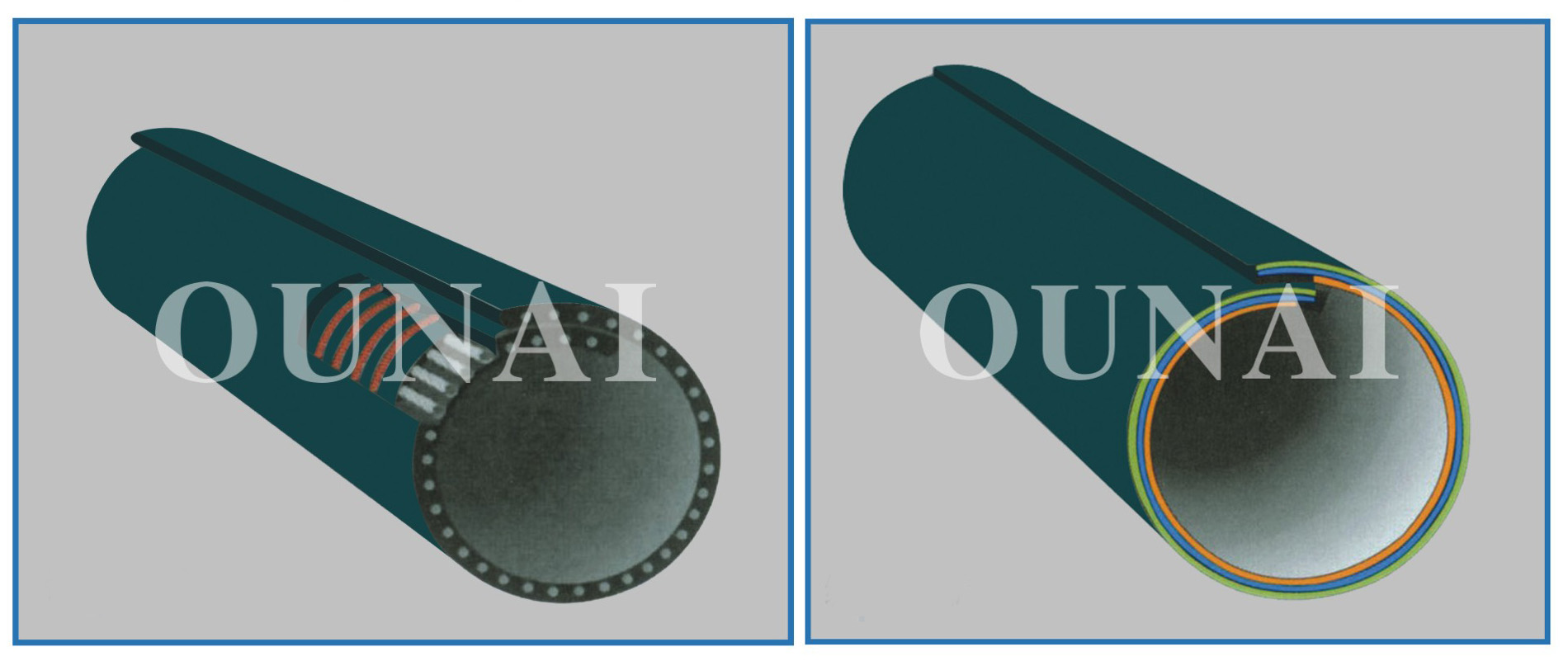

Construction:

The belt cord of

tubular conveyor belt takes high-strength canvas or steel cable as its carcass

in combination with high-strength high abrasion-resistance high-quality rubber

as the top and bottom rubber cover, during the operation, the rubber belt is

changed gradually from flat plane to U shape and finally is rolled into tubular

shape so as to achieve enclosed conveying.

Features:

(1) In order to

make the rubber belt takes on circular tubular shape, the tubular belt itself

has appropriate transverse rigidness, which can ensure good retention and seal

of tubular shape.

(2) The belt body

has good elasticity and longitudinal flexibility, making the belt able to

tolerate repeated and long-time violent bending and shrinkage;

(3) The belt has

excellent physical and mechanical properties. Because when the tubular belt is

conveying material, its belt body is stretched, and the cover rubber is long

exposed to sunshine and weather, therefore, it is required that the outer cover

rubber has higher resistance to weather, ozone, ultraviolet rays, flexure,

cracking etc., while inner cover rubber should have excellent abrasion

resistance.

(4) Because of

special structure of tubular belt, it conveys powdery material in tubular

closed condition during the conveying, thus it can effectively prevent dust fly

and spill. This not only avoids pollution to the environment and material

wastage, but also can prevent exposure of material to sunshine, wind and rain,

thus ensuring the quality conveyed material.

(5) By adopting

tubular conveyor belt for conveying, the material is wrapped in the rubber

belt, this increasing the area of contact between material and rubber belt and

internal friction angle of material, thus can increase the inclination angle of

material conveying of the conveyor. Ordinary conveyor belt only has 22°

inclination angle, whereas that of tubular conveyor can reach over 30°,

therefore, increased inclination angle of conveyor can shorten the horizontal

distance of the conveyor and save investment.

(6) With tubular

belt adopted for conveying, after the belt presents tubular shape, it can run

horizontally, vertically or curvilinearly, the conveying line can be arranged

according to the space within a certain range without setting intermediate

transfer station, therefore, construction investment can be saved.

(7) Tubular belt

conveying avoids bias with reliable running, improved conveying efficiency and

better economic benefit and lower running cost.

(8) With tubular

belt for conveying material, the return run after discharge can also convey

material, i.e. two-way conveying. This can not be achieved with ordinary

conveyor belt. Because the return belt also presents tubular shape without

material spill, there is no contamination and cleaning cost for the complete

system.

Application:

It is widely

applied in enclosed conveying of bulk materials in the sectors as of

metallurgy, electric power, chemical engineering, harbor, wharf, building

materials, coal, mine, grains etc. It has multiple types such as

abrasion-resistant, heat-resistant, cold-resistant, corrosion-resistant,

flame-resistant, antistatic etc.